About IDC Termination, While making decisions for wire harness making, you might confuse using a ribbon cable with an IDC connector or a discrete cable with a crimped or soldered connector.

Both types work perfectly fine, given that they are compatible with the application.

IDC and other wire harness connectors are reliable options with pros and cons.

This article will look into these two popular wiring solutions for a better view.

What is an IDC Connection?

IDC stands for Insulation Displacement Contact or Connector.

This name also describes how the connectors will attach to the wire conductor.

On the back of the connector are two rows of twin-fork shapes, each with sharp edges and a U-type area between them.

Also, the offset between these rows is half of the pitch of the connector.

For instance, if you use a connector with a 1.27mm pitch, the offset will be 0.635mm, ready to fix a 0.635mm ribbon cable.

As you push the ribbon cable into the row of contacts, the sharp forks pierce into the wire’s insulation, peeling it away from the conductor.

When you fix the cable further, the conductors reach the end of the U-shaped channel and join it to regulate the flow of signals.

How to make IDC cable?

Making an IDC cable is simple when you understand the phenomena of the IDC connector.

For this purpose, you will need

- One IDC connector

- 0.05″ ribbon cable (rainbow or grey/red)

- A Vise

After collecting the things, you can follow this simple procedure.

- To insert the cable into the connector, align the cable with the pins of the IDC and push it. If you have a grey cable with a red index line, set the index line with the Pin1 indication point. Moreover, remove the extra pins of the connector if your cable is smaller.

- Press the connector onto the cable so the pins go through the rubber insulation and fix the conductors. For that, you can use a vise. Just press the connector and cable inside it until the assembly is fixed.

- For better protection, some IDCs come with strain relief brackets as well.

- To attach them, bend the wire over the top of the connector and then snap the bracket in place.

What is a Discrete Cable?

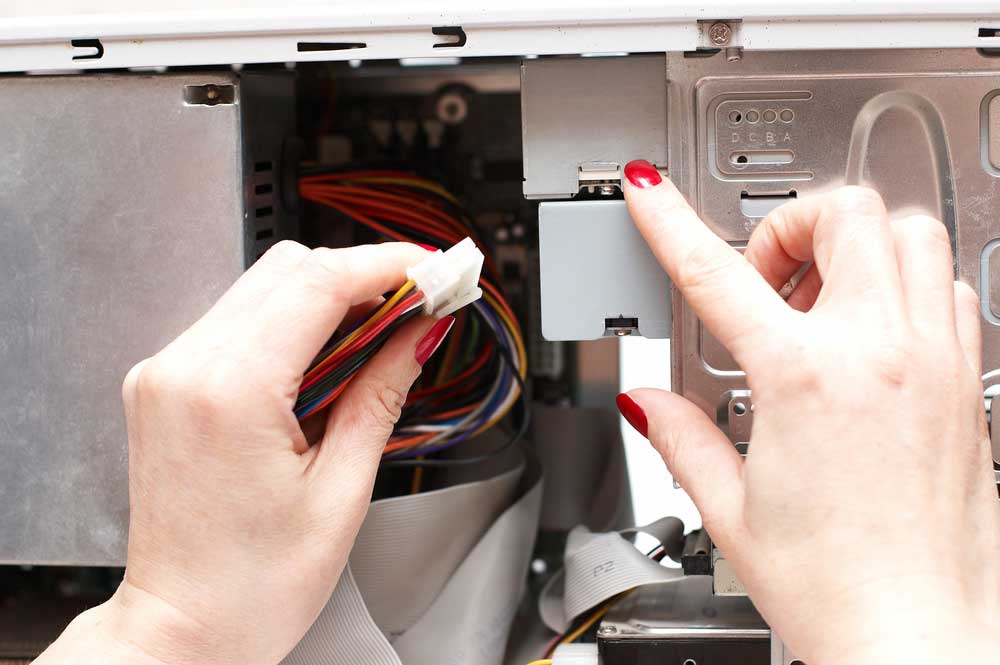

Caption: Electric socket wire connector

Discrete cable is just a fancy term to describe simple wiring solutions.

It consists of a solid or stranded cable upon which you can fix a single connector by soldering or crimping.

Although solder cups are already on the connectors, you must assemble the crimp contacts yourself.

How to make a Discrete cable by crimping?

To crimp the connector, perform the following steps.

- Take the wire and strip the insulation from the end where you want to crimp the connector.

- Now, grab the crimping tool and fix the wire inside it. Crimp the insulation and the bare wire part together if the tool has two different teeth. If not, you have to make individual crimps on them.

- Then, take the connector pin and set it inside the crimper with grooves facing the inside of the tool. Squeeze the crimper so that it bends into a heart shape.

- At this point, loosen up the tool and insert the crimped wire into the pin.

- Apply firm pressure and fix the pin onto the wire, ensuring that the pin properly covers the wire and is ready for further use.

- Finally, put the crimped pins into the housing, which keeps the pins separate and easily pluggable.

How to make Discrete cables by soldering?

To solder a connector over a discrete cable, follow this process.

- To start, remove the insulation from the end of the wires. For efficient removal, you can use a stripper and remove about ¼” or 6.3mm of insulation.

- Next, in the wire with a thin layer of solder. Here, you will use a hand tool to hold the wire in place and apply rosin flux on the bare area. Then melt it with the help of a soldering iron.

- As the wire is hot, put the solder material on the contact point of the wire and iron.

- Then insert this area into the pin and cut off the extra length of wire.

- While holding the connector with a vice, place the soldering iron tip on the connector pin and make it hot. Put the solder over and inside the connector pin to completely cover it with the material.

- While keeping the soldering iron onto the pin, insert the wire tip properly. Also, add some more solder over it to cover it completely.

- In the end, remove the soldering iron and clean its tip from any flux it has.

Leave the solder over the connector and wire and let it dry.

After some minutes, you will observe a strong, shiny joint holding them together.

Major advantages of IDC cable

Using IDC connectors gives you one big benefit, i.e., you can snap all your connectors over the cable with a single push.

An IDC connector comes with a bar, which goes to the back of connecting points and pushes the ribbon wire into the right place while covering the sharp edges.

Moreover, it ensures that these contacts remain reliable for longer, and you do not end up with loose ends.

If you are using a narrower ribbon cable, chances are that you snap the IDC connector with bare hands.

However, if the cables get broader and more complex, it is better to use a tool.

This tool will be similar to a clamper or a vice and help you fix the contacts and the bar with the conducting strands.

Fixing the IDC connector is much easier and quicker than assembling a discrete wire where you need to go through different steps.

These steps take a lot of time and effort, like stripping the insulation, crimping or soldering the contacts, inspecting the connection, and assembling the wire harness into its housing.

Although with IDC, you skip the whole hectic process. Still, not all assemblies can contain ribbon cables.

Why is Discrete Cable a win over IDC?

Caption: Discrete Wire Cable Assemblies

Discrete cabling is indeed an important part of the cable harness industry.

While the process behind its assembling is long, it can still give you many benefits like

- Cable sizing: In IDC cables, you need to use connectors by the size of your cable. If it is slightly bigger or smaller, you won’t be able to properly fix the strands inside the U-shaped area of the forks. Also, different IDC cables require specific connectors, even if they are solid or stranded. However, in discrete cabling, you can crimp or solder whatever contact you want with the cable you have on hand. Hence mix and match is easier here.

- Cable Duplication: If your design calls for different IDC connectors like 10, 20, or 30-pin, you have to use ribbon cables of 10, 20, or 30 strands. Not only will it affect the circuit space, but it will also get heavy on your pocket. But, with discreet cabling, you can easily use a single cable reel with different connectors attached at all the connection points.

- Routing: With ribbon design, routing the cables through different nooks and corners becomes difficult and risk-taking. On the other hand, single discrete cables are more flexible and easier to go through any obstacle.

- Availability: IDC connectors are generally difficult to design and manufacture, so fewer choices are available. Also, you can only find the ribbon cables at a maximum of 22 AWG, which is not good for high-end constructions.

Discrete-Wire cable assemblies at Cloom

Cloom can offer you a wide range of discrete cable assemblies that

- Meet the industry standards like UL product specifications, 2011/65/EU RoHS compliance, etc

- Have manufacturing area certifications like ISO 15001, DIN ISO 9001, ISO 13485, etc

- Comes with cable ties, heat-shrink tubing, woven braiding, and sleeves

- Have a wide range of connectors

- Multiple configurations include single or dual ends, straight or branched into different setups.

All these features facilitate the engineers to pick and choose the cable they want from the inventory.

IDC cable assemblies at Cloom

Cloom does not stop at only having discrete cables and can also provide you with unique IDC cable solutions.

Here, the IDC cables also meet the industry and manufacturing facility standards while providing you with the best quality they can give.

Moreover, these cables

- Are available with different IDC connectors size for widening the application

- Have different configurations using different lengths of cable and Orientations.

- Have a range of quantities so you do not run out of them during the process.

Conclusion

The choice of termination solely depends on the level of performance you need for your application.

After choosing a connector, you will see each cable option while keeping the routes and other environmental factors in sight.

Budget can also be a large factor when deciding on the cable assembly.

Cloom offers a variety of cable experts that can resolve your problem and give you the ultimate solution.

We focus on connector and cable uniformity and build both on the same plant. This ensures that every assembly part is aligned well, offering a long-lasting connectivity solution.

For further details on the matter, you can contact us here and have a chat with our panel.