The demand for better quality and higher production has significantly impacted the innovation of various wire termination techniques.

Originally, we used simple clamps to terminate the wire, but with technological advancements, various other methods to terminate wires occur.

What Is A Wire Termination?

A wire termination refers to the work done at the end of an electrical wire that allows it to connect two or more electrical devices (terminal, switch, and connector).

There are several types of connections across all industries; however, they can all be summed up into three groups; crimped, IDC, or soldered.

Wire Termination Types

Below are the various types of wire terminations.

Solder Termination

This type of termination occurs when you melt an open connector to seal it to create a strong bond, forming an overall permanent connection.

Before solder termination, the desired wires or cables must remove the insulation’s end and apply the flux.

Different kinds of flux also need periodic maintenance as some may damage the connections or surfaces over time.

Further, solder terminations are not widely used since their construction tends to be more time-consuming than crimp options.

Crimp Termination

The most commonly used wire termination method is crimping termination because it provides mechanically strong and clean terminations at quick speeds.

For fieldwork or low volume, you can use an abundance of handheld crimping devices, a cost-effective method.

An increase in volume will influence the level of automation.

Terminals available in a continuous strip form allow feeding and crimping in crimping applicators, which are designed with interchangeable die sets to eliminate the adjustability of tools.

Also, the interchangeable die sets eliminate errors to ensure near-perfect crimps and increase flexibility.

Place the applicator in a fully automated machine or benchtop crimping press.

You don’t have to worry about your applicator fitting in presses made by different manufacturers because all models are standardized to fit in all presses.

The level of quality in crimp connections depends entirely on the intended application.

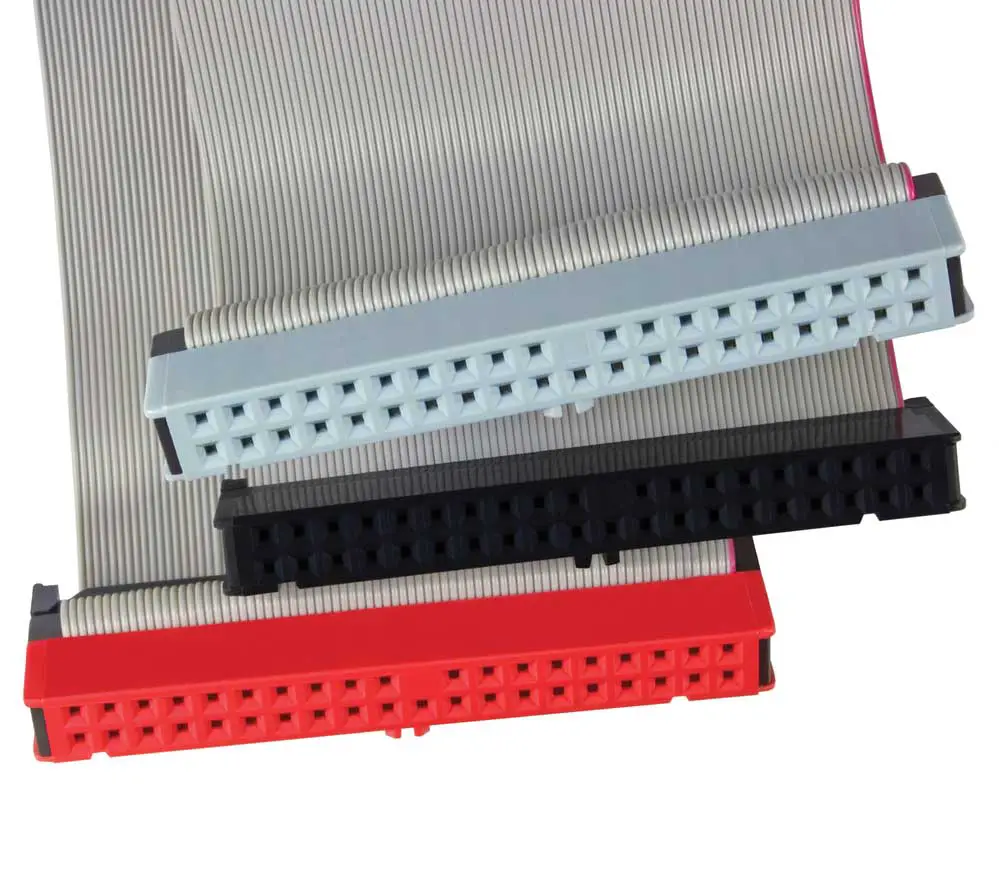

IDC Terminations

This type of termination is typically used for mass termination of ribbon or flat cables.

Its technology allows the connector to simultaneously contact each terminal of the conductor wire, like a sharp blade piercing through its insulation.

Ribbon Cable

Every connector strand can create a metal-metal connection with the wire assembly part when the connector gets deformed.

Such a scenario eliminates the need for stripping the insulation before making a connection.

Terminate Wire Ends at Cloom

For all your wire and cable termination, feel free to contact Cloom Tech.

Wire Termination Options

- End Cut – Cut wires even based on specifications provided by the customer.

- Wire Slit – Separated parallel wire ends from each other per customer specifications.

- Wire strip- Strip the wire insulation to expose the inner strands based on your specifications.

- Stagger Cut -Cut wires and strip them at varying lengths based on certain specifications.

Cable Termination Options

- Blunt Cut – cut the cable even based on the customer’s preferred length.

- Remove the Outer Jacket, sometimes called ROJ- Peel off the cable’s outer insulation to expose the inner wires. The client typically determines the length.

- ROJ and Stripped Wires – Remove the outer cable jacket, then strip the wire insulating material.

- Stagger Cut – Eliminate the outer jacket, and strip the wires at varying lengths.

Termination Connectors

- Quick Connect – This connection is available in the pre-insulated, un-insulated, fully-insulated, and right angles.

- Ring Terminal – This terminal is for a ground connection when attaching the product using a bolt or screw.

- Spade or Fork Terminal – This is quite similar to the ring terminal, with the primary distinction being that it can be removed without completely unscrewing the bolt or screw.

- Ferrule Terminal – This terminal primarily works with terminal blocks. It is also used when crimping and securing some of the bare copper strands. Another important element is that consumers can get it in double ranges for crimping two individual wires.

- IDC Connectors- IDC stands for Insulation Displacement Contact, which is otherwise known as Insulation Piercing Contact (IPC), whose design is capable of connecting to the conductors of insulated wires via enhancing a specific sharpened blade through the insulation, forgoing the need to peel the conductors of the insulation before connecting. In another word, if the connector is properly designed, the connector blade cold welds to the connector, making a theoretically gas-tight connection.

Ground Wire Connection

Conclusion

Proper wire termination ensures smooth running and optimum efficiency of electrical systems, which is an important factor across most industries.

However, with numerous methods to terminate wires, it’s important to fully equip yourself with the proper skills and knowledge to ensure the job is done right.