What is a lead wire?

While you can use simple wire harnesses in many applications, few areas of use will need lead wires due to their extensive production specs.

Whether using lead wire in a sophisticated electronic application or a household product, the lead wire must meet strict military, industry, and government standards for electrical harness fabrications, interconnection circuits, and internal wiring.

In this article, we will look into the basic of lead wire.

What are Lead wires?

Lead or hook-up wires are the single-conductors in any appliance’s internal wiring.

It is also known as appliance wires and is popular for various applications, including military equipment, power and control circuits, switchboards, motors, panels, rectifiers, and transformers.

Popular hook-up wiring harnesses include:

- Basic appliances wiring

- Business machinery wiring

- Meters wiring

- Automotive wiring

- Control Panels wiring

- Computer wiring

- Electronic equipment wiring etc.

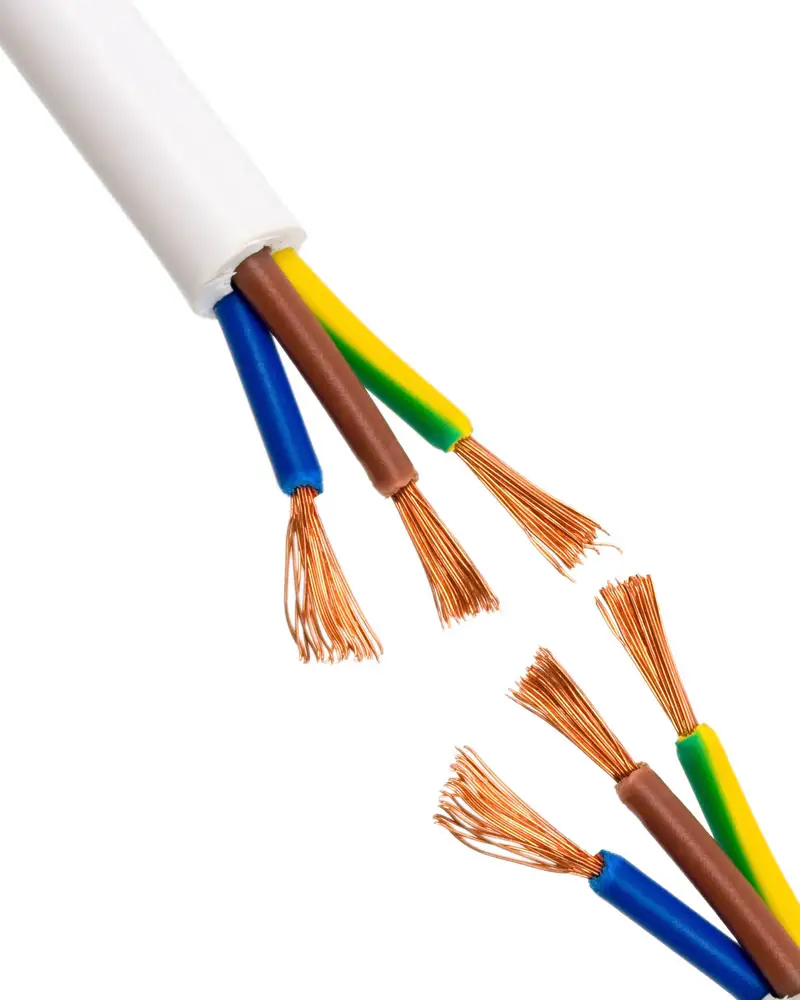

Stranded Electrical Hook-up Wires

Features of Electronic Hook-Up Wire

Lead wires have various ways of construction, due to which their properties and application area may change.

Hence, these wires vary by their compliance, making material, insulation, color-coding, etc. Here is the detail of each feature.

CSA, UL, and Mil-spec compliance

Primarily, hook-up wires follow the three distinct compliance bodies: CSA, Mil-spec, and UL.

The wires having these ratings may seem like the same product. However, they do vary in their internal properties.

For example, the CSA standard includes the REW, TEW, SEW, and Type SIS wires.

Moreover, the CSA also takes responsibility for additional approvals that link to the area of usage and the use itself.

UL is similar to the CSA rating but has different standards for the specific gauges.

As far as Mil-spec is concerned, it also differs in the voltage rating for different wires and can go beyond 600V.

However, in most cases, it may be an alternative to CSA or UL wires; you can use them when these two wires aren’t available.

Special Wire properties

The lead wires use copper as the inner conductor material for its excellent conductive properties while resisting corrosion and enduring higher thermal energies.

Moreover, you can find it solid or stranded according to your need.

Solid wires consist of single, thick copper wires, while stranded wires consist of thin strands of copper twisted together, making the cable more flexible than the other.

Other properties can be

- Length (2 inches to 324ft)

- Wire Gauge (10 to 28 American Wire Gauge (AWG)). The thicker the wire, the higher the voltage and temperature value it can endure and pass through.

- Crimping style (Single-end or double-end)

- Crimping force for better attachment

- Open and Closed barrels

- Termination type (insulated or non-insulated)

Best for low-voltage uses

Rated Voltage of a lead wire plays an important role in deciding the other aspects of the wire construction, for instance, the thickness of the insulator.

If you categorize the general applications in terms of voltages, the following will be the classes of the applications

- Low Voltage requiring less than 1kV

- Medium Voltage ranging from 1kV to 36kV

- High Voltage requiring greater than 36kV of rating.

Hook-up wires are generally best for low-voltage uses; thus, their construction and usage are simpler than other wires.

A broad range of insulations

Insulation or jacketing material creates a barrier between the conductor and the outer world while protecting the wire and the person operating it.

Hook-up wires usually use plastic, rubber, silicon, and other materials as jackets, according to the design.

Now, you can find the PVC or thermoplastic insulations on UL-rated lead wires like UL1007, UL-1015 or MTW, UL-1061, UL-1569, and mil-spec wires like MIL-W-76B, etc.

You can find these cables in the internal cabling of meters, panels, and military equipment.

XLP, XLPE (Cross-linked Polyethylene) insulations are on the lead wires like UL-3173, VW-1, or SIS-rated wires.

These hook-up wires are for switchboards and control panels used on industrial levels.

TFFN or TFN wires are wires with thermoplastic insulation with nylon sheathing.

They are best for machine toll wire or MTW applications and can be found as appliance and fixture wires.

At the end comes the high-temperature lead wires with Teflon (EFTE, PFTE) or flexible silicon insulations.

You can configure these materials as per your own need while they will operate smoothly on higher temperatures of 200 degrees and even higher.

These applications are special cases that do not occur mostly, and if they do, they also require higher gauge sizes for extra endurance.

Either way, they will need high-temperature lead wires for the application.

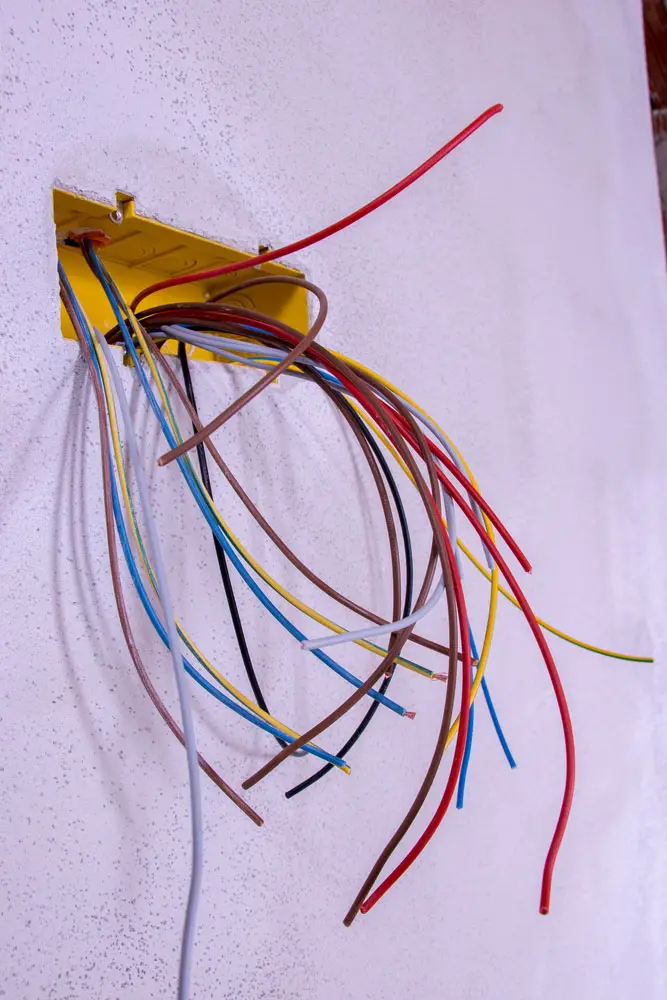

Color-coded insulation for smooth circuit classification

Wires are color-coded by using different color insulation the wires. These codes indicate the use and the Voltage a single wire carries.

While the purpose is the same, each standard body uses its coding system for each application.

For example, NFPA or National Fire Protection Association uses a solid color with a strip of any other color for its wires, while the MIL and NEC use base colors for different uses.

Color coding of wires

Steps to Build a Wire Harness with lead wires

Building your wire harness is a trickier task than one seems to think.

Thus, one may step up for it when they need a custom wire for their application or want to make it easy to understand appearance-wise.

Here are the basic steps to construct a wire harness that you can follow if you are new to the game.

Create a Wire Diagram

Before starting the wire harness manufacture, you must draw out the structure for better planning.

You can make the wiring diagram or structure with the help of tools like CAD and similar software.

Each diagram has two parts, schematics, and harness design.

The schematic shows the components you will use, their location, and how you will connect them, while the harness will tell you how every component will be put together.

While creating a harness diagram, you can use different colors and symbols to represent each component.

For example, engineers use different color circles for the connectors and simple lines for the wires.

This helps the manufacturer to understand the requirement and makes the process organized and easy.

Select Tools

The next task is to collect all the tools for the job. Basic wire harnessing requires

- Wires

- Terminals

- Connectors

- Zip ties

- Wire Cutter

- Wire Stripper (manual or automatic)

- Crimping Pliers

- Heat Gun

- Heat Shrink Tubing

- Multimeter

The type of heat shrink tube will vary according to your intended application.

For instance, PVC-insulated GXL wires are better for high temperatures and harsh areas.

Strip the wire

Using the wire stripper, remove some part of the insulation from the ends of the wire.

As you will attach these ends to the terminals, strip the length of the wire accordingly.

Cut the Heat-shrink tube.

Take the heat-shrink tubing and cut the required length out of it.

For now, slide the tube over the wire and keep it on the unterminated wire area.

Connect the terminals

Take the terminal and crimp the seam slightly before sliding it onto the stripper area of the wire.

Now, connect the wires to the terminal while putting them together and crimping them hard with the crimping pliers.

The crimp should be strong enough to bind the terminal and the wire with each other while the wire remains undamaged.

Cover the Wire

Slide the previously inserted heat-shrink tube over the crimped terminal and wire while ensuring that it covers the whole part properly.

Shrink the tube

With the help of a heat gun, slightly heat the tube so that the tube sticks over the join.

It will make an insulation layer over the exposed crimp and protect it from external conditions like moisture, cuts, dust, etc.

Conclusion

Hook-up wires have color-coded conductor strands with different gauge sizes, so you can choose the thickness depending on your need.

At Cloom, we can provide various hook-up harnesses, including one for internal appliance wiring, transformers, vending machines, panels, motors, and much more.

We also have categories of wiring harnesses specifically designed for low-voltage and higher-voltage applications.

Moreover, you can get a range of Mil-spec wire harnesses for all critical military equipment and automotive.