This article will go through one military product, i.e., a Mil-spec wiring harness.

Military and aerospace operations are critical, and one cannot afford to fail them at any stage.

Failing such operations not only interrupts the process but may jeopardize human life.

Thus, every machine, equipment, or even the smallest product should be high-grade.

Most military operations use equipment that passes through specific military standards designed to meet the worst environmental conditions.

What is a mil-spec wire harness?

As military and aerospace applications require exposure to extreme environmental conditions, the cable assemblies must be reliable and high-quality.

Military cable assemblies and wiring harnesses are specially designed and engineered products that meet MIL-SPEC requirements.

The components such as wires, cables, terminations, connectors, and many others used in manufacturing these assemblies must be suitable for military applications.

Military cable assemblies are perfectly suitable for medium and high-temperature applications to perform maximum, even under high mechanical stress.

Also, these assemblies work under high-frequency electronic applications with very high temperatures offering stable electrical characteristics with minimal power loss.

Standards of military cable assemblies

Several mil-spec standards differentiate military cables and wires from others.

Some private organizations such as SAE, ANSI, and NEMA have also developed their standards.

Cable manufacturers can refer to these military standards while picking materials and manufacturing military-grade cable assemblies.

Mil-Spec wires and cables:

A mil-spec wire must follow certain standards to fall into the category; for example,

M22759 (SAE AS22759)

The wire suits aerospace applications requiring extreme conditions, such as electronic systems used in harsh weather, intense moisture, or aircraft engine controls.

M16878

You can also refer to it as MIL-W-16878, and this category can bear high temperature and high voltage ratings.

Having PVC, PTFE, ETFE, or Polyalkene insulation, these wires are suitable for every military product and thus come with different slants M16878/5 is ideal for high-temperature electronics.

At the same time, M16878/4 is best suited for power supply and appliance wiring.

M25038

Applications requiring exposure to vibrations, flame exposures, and other similar harsh environments need this wire. M25038 is suitable for critical aircraft circuits.

M13486

Cables used for low-tension military purposes must meet this standard. These cables are found in tanks, trucks, and other ground vehicles.

Like several other military specifications, this standard has different slants to meet additional product requirements.

Cables and wires of this standard are moisture and abrasion resistant and remain flexible at low temperatures.

M5086

Wires and cables under these standards are useful in broad aerospace, military and industrial applications.

These wires have a copper conductor with tin plating having PVC insulation and an outer nylon covering.

All applications requiring resistance to moisture, impact, abrasion, and exposure to chemicals use M5086 wires and cables.

Military cables and wires find their use in electrical equipment, electronic components’ internal wiring, electric panels, and meters of military vehicles.

Military wiring applications include bonding moving parts, point-to-point wiring, airframe wiring, and areas requiring durable wiring.

Mil-Spec Connectors

These shell-type connectors protect electric connections from various environmental factors, making them suitable for military and aerospace purposes.

Connectors comprise a mating pair with a receptacle and a plug, and each mating pair has a male pin or a female socket.

Electrical connections are of phosphor bronze or beryllium copper with gold or another non-corrosive and high-conductive metal plating.

Mil-spec connectors also meet some military specifications, including:

RoHS compliance

RoHS, or Restriction of Hazardous Substances, is a European Union directive under which all electronic and electrical equipment manufacturers must manufacture products with minimal hazardous substances like cadmium, lead, chromium, polybrominated diphenyl ether, and many others.

MIL-C-5015

This standard implies the cylindrical connectors used in electronic interconnection systems in commercial and military applications.

In this category, you can find cylindrical connectors with soldered or removable crimped contacts.

Based on the connector class, these connectors are suitable for a 55 to 200 degrees Celsius temperature range.

MIL-C-22992

All heavy-duty connectors used in military and industrial applications with multiple contacts with quick connect/disconnect plugs and receptacles fall under this category.

These connectors can support high power levels and withstand a temperature range of -550C to +1250C.

MIL-C-26482

Two series of quick disconnect, mini, and environment-resistant circular connectors come under this category.

Each series has hermetic receptacles. Using these two connectors of two series when using power contact is possible, but the same is not possible when you use shielding contacts.

MIL-C-26482 Series I connectors are small-sized with strong electrical, environmental, and mechanical properties and thus are used in military communication systems.

MIL-C-26500

The environment-resistant miniature circular connectors fall under this standard and meet rockets, missiles, aircraft, and space vehicles requirements.

These connectors have a series of plugs and receptacles; plugs or mating pins have resilient or hard faces, while sockets have resilient faces.

MIL-C- 27599

This standard covers high-density, miniature, quick disconnect, environment resistant, bayonet coupling electrical connectors capable of working from -65C to +175C.

It is possible to intermate these connectors with MIL-C- 38999 series I and II.

MIL-C-38999

Two series of high-density, miniature, quick disconnect, environment-resistant, bayonet coupling electrical connectors fall under this category.

These connectors can work under the temperature range of -65C to +175C. It is possible to intermate these connectors with MIL-C- 27599 series I and II.

MIL-C-81703

This standard includes three electrical connectors: mini, circular, and environmentally resistant.

These connectors can have crimp (removable) or solder (non-removable) contacts.

MIL-C-83723

This series is now inactive owing to the MIL-C- 26482 series II, as these two are identical as per the decision of the Department of Defense.

MIL-DTL-5015

This standard includes workhorse connector specifications of the military aerospace industry.

The MIL-DTL-5015 combines the best features of old solder 5015 and standard rear accessories of MIL-C-26482 series II and MIL-C-83723 I and II.

As a result, these connectors are perfect for ground support and airframe industries’ requirements for reliable rear-release connectors.

MIL-DTL-32139

The defense supply center in Ohio administered this joint service specification covering nano-miniature plastic and metal connectors.

MIL-DTL-38999

This standard covers four electrical connectors: mini, highly dense, threaded, bayonet or breach coupling, environmentally resistant, and circular.

The contacts can either be removable crimp or fixed solder. These connectors can perform well under a temperature range of -65 to +200 degrees Celsius.

MIL_DTL-83513

The defense supply center in Ohio administered this connector specification as a changed version of MIL-C-83513, released in 1985.

The revised version came in 1997 to include performance-driven specifications. Both metal-shell and plastic micro-D connectors come under this standard.

MIL-DTL-83723

These connectors fulfill circular electrical connectors, related contacts, and environmental testing requirements.

These connectors come with crimp/solder contacts and can work in specified ranges.

ARINC

ARNIC standard is meant for the avionic industry, and a connector complying with this standard is helpful in interfacing avionic equipment.

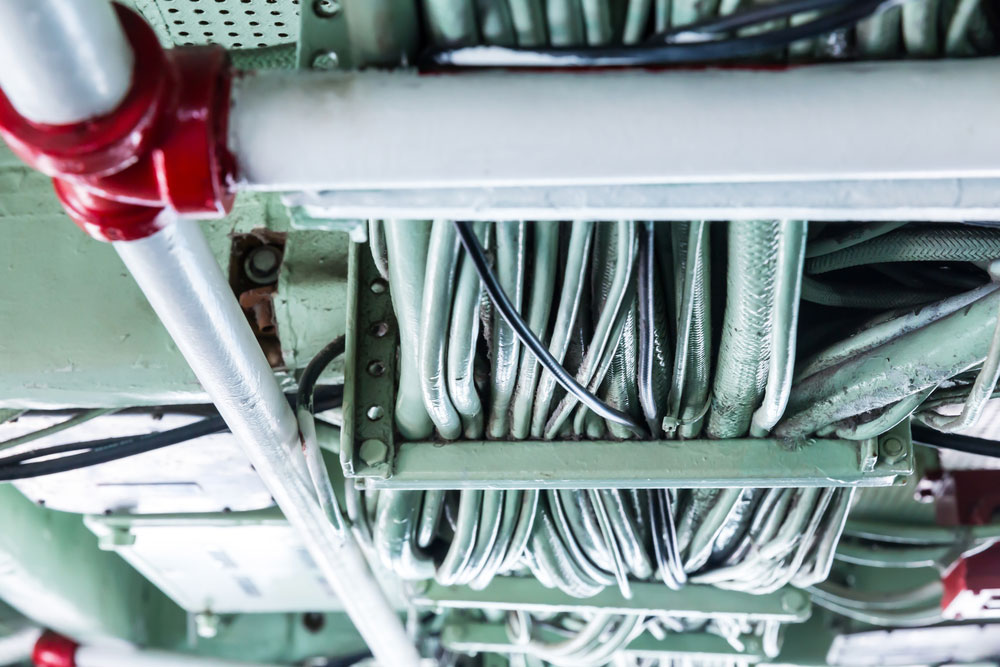

Military ship pipeline and wiring

Features of military cable assemblies

Aerospace and military operations need reliable wiring and cable assemblies for safe equipment operation.

Thus, the military cable assemblies are supposed to have the following qualities:

Mil-spec wiring harness: Ruggedization

Military cables and wires should be highly rugged to meet the rigorous military-grade criteria of security and aerospace applications.

The cable assemblies should be high-performing and robust for such harsh environmental conditions.

Mil-spec wiring harness: Miniaturization

Security, Military, and aerospace industries need miniature components installed in their devices, machines, and vehicles.

Nowadays, you can find highly miniaturized cables and connectors, which are equally robust and efficient as their bigger versions.

However, at the same time, they are much lighter, more flexible, and can integrate easily.

With miniaturized components, it becomes easy to use extra space for critical military operations.

Mil-spec wiring harness: Microwave and RF

Military cable assemblies can work in the frequency range of 4GHz to 40GHz.

Several microwave and RF products can also work in the frequency range of 110 GHz.

Applications of military cable assemblies

Military wiring harnesses and cable assemblies are suitable for several critical military operations, including:

- Military ground machines and equipment

- Air communication and navigation systems

- Control of remote weapons

- Inter-shelter and fields communication equipment

- Avionics systems

- Space force systems

- Space shuttles and satellite

- Ships, submarines, and other marine systems

- EMI sensitive equipment

Space shuttle launch

Hook-Up Wire vs. Mil-Spec Wire: Which is better?

Choosing the right cables can make a significant difference in application processing.

Mil-spec wiring harness: Hook-Up Wire vs. Mil-Spec Wire: Similarities

Hook-up or lead wire refers to the cable having one conductor and is used in the internal wiring of appliances.

Despite this, you can use hook-up wire cable assemblies in various applications, such as control cables, power cables, switchboard wires, and motor cables.

Military cables also have one conductor similar to hook-up wire and are similarly used in the internal wiring of appliances.

Their range of applications is also identical to the hook-up wire. Thus, all mil-spec wires are hook-up wires except data and communication cables.

Mil-spec wiring harness: Hook-Up Wire vs. Mil-Spec Wire: Differences

The only difference is that mil-spec wires are more flexible hook-up wires which can withstand high-temperature ranges.

Regular or common hook-up wires are unsuitable for military purposes in the United States.

These wires follow UL and CSA standards, where UL is a united state standard while CSA is a Canadian one.

Common hook-up wire standards are UL 1015, UL 1061, UL 1007, and UL 1569.

On the other hand, mil-spec wires are only certified and approved for military standards and applications and nowhere stand in UL and CSA standards.

The direct analog of UL/CSA hook-wire is M16878, in which the first nine products of this military wire are direct analogs to standard hook-up wires with varied specifications.

While some other military wires like M22759 or M81044 have different construction and thus are not direct analogs of hook-up wire falling under UL/CSA standards.

Mil-spec wiring harness: Hook-Up Wire vs. Mil-Spec Wire: Can you use them Interchangeably?

You cannot use a regular hook-up wire for military applications. However, using the mil-spec wire for non-military uses is fine for applications not requiring UL/CSA approval.

However, as military cable assemblies are expensive, you must know whether your application needs a mil-spec cable or a general lead wire that can solve the purpose. Here are some situations in which you must use mil-spec cable assemblies.

- If your application is critical and failing can put the entire process in danger and may lead to heavy losses, then you need a mil-spec cable. The durability and sturdiness of these cables ensure the process’s continuity; thus, investing in them would be a wise decision.

- If the cables and wires you use will face harsh and unpredictable environmental conditions, regular wires and cables won’t work. Get high-quality and robust mil-spec cable assemblies in such situations as they can work in a wide range of temperatures from very low to very high. Further, these cables are abrasion and corrosion-resistant.

- Equipment, machines, and other devices undergo continuous motion and vibration in some applications. A standard lead wire cannot bear high vibration, and mil-spec cable assemblies are also the right choice. These cables can withstand extreme vibrations and movement, ensuring the smooth working of the equipment.

- If your application involves exposure to electromagnetic radiations or radio frequencies, military-grade cable assemblies are a must, as they are correctly shielded from these vibrations.

- Some applications have safety concerns and require product stability during the process. You may need to pick mil-spec assemblies based on such specifications that applications demand. Further, sometimes, you must choose military-grade cables to comply with the industry standards and requirements.

Custom Military cable assemblies from leading cable assembly manufacturer, Cloom

You must pick reliable, high-quality, and precisely tested cable assemblies and wiring harnesses for military and aerospace applications.

At Cloom, we design and manufacture superior quality mil-spec cable assemblies that meet virtually all standards, including MIL-STD_1460, MIL-STD-2000, and J standard-001 class 3.

We also offer 38999 connectors and circular connectors, which we can overmold as per your requirements.

We can also incorporate potting and pre or over-molding to the cable assemblies to make them perfect for the application specifications, such as vibration-resistant, abrasion resistant, and waterproof to IP67 and IP68.

You can be assured of our cable assemblies as they are perfect for extreme temperatures and weather conditions involving severe wind and moisture.

Conclusion

Military cable assemblies are durable, light in weight, and have rugged properties.

The materials used in its manufacturing make the assembly resilient, especially in situations like high vibration.

Now, pick the best quality cables available with Cloom.