Manufacturing cable assemblies and wire harnesses are fine if you hire expert contract manufacturers who will simplify the complex process while taking the burden off your shoulders.

Let’s see how they can help produce the cable assembly and wire harness.

Wire Harnesses vs. Cable Assemblies

Wire harnesses and cable assemblies are often used interchangeably because they have the same purpose: to regulate the current and signals within different systems.

But they are slightly different in uses and manufacturing processes.

| Wire Harness | Cable Assembly | |

| Definition | More than one wire inside a protective shielding | More than one wire or cable inside a protective insulation |

| Industry Applications | Medical equipment, military devices, alternative energy products, electronics applications, vehicles, and auto machines | Military devices, aerospace, Vehicles, medical equipment, electronics, lighting, and other multi-function purposes |

| Sleeve Material | Vinyl, Thermoplastic Rubber, Heat-shrink Thermoplastic | Vinyl, Thermoplastic Rubber, Over-mold Thermoplastic |

| Advantages | Protection against environmental problemsExtended life span of wiresLess expensive | The safer option improved stain relief and pulling strength organized cabling. |

Custom Cable Assemblies and wire harness Options at Cloom

At Cloom, we offer these services to our customers.

Low Voltage Hook-Up Wire Harnesses

With single or multi-conductor cross-sections, you can find 300 V or less low-voltage hookup wires at Cloom.

Also, these hookup wires will greatly benefit you if you produce everyday appliances, industrial machinery, and medical equipment.

Data & Video Cables

We offer cable assemblies with popular industry standards like D-Sub, HDMI, USB, RCA, DisplayPort, and other different types for data and video.

These types may also contain male and female mini, standard jacks, and plugs.

For USB, we have “A,” “B,” and “C” connector types. Ethernet has multiple variants, including the popular RJ45 and RJ11 (usually for the telephone).

Furthermore, these wires come with strain relief and an extra layer of protection to increase tolerance and ruggedness.

Custom Over-mold Cables

There are a variety of cables with custom-designed over molds to protect sensitive electrical components and fragile connections within the assembly.

Furthermore, these over molds allow adding handles, artwork, and encapsulating PCBAs.

At Cloom, we ensure that the over-mold materials are tightly bonded to the cable jacket, making it water-resistant and tough for rough usage.

Hence, the fragile connections within the assembly remain safe and well-shielded.

Flat Flexible Cables & Ribbon Cables

At Cloom, we manufacture these cables according to your needs with just 2 to more than 60 conductors with industry-based standards.

The most used ribbon cable is 0.050 pitch with 28AWG UL-approved design. The flat flexible cables also contain a gray stripe on one end which indicates PIN1.

Custom colors and extrusions are also available.

Shielded Cable Assemblies

Shielding is a powerful way to protect cables from external environmental damage like corrosion, chemicals, or water.

Hence, Cloom provides various shielded cables ranging from simple-grade small to military-grade complex power cables.

At Cloom, we provide shielded cables only after analyzing different factors such as program requirements, signal integrity, and mechanical constraints of the system.

Since shielding adds cost and weight to the cable, it’s only designed when its needs are eminent.

Power Cables

Power cables consist of tinned copper conductors, connectors, thermoplastic over molds, and PVC jackets.

Cloom manufactures all different types of power cables, including NEMA 5-15P and 5-15/20.

Furthermore, we also provide different types of power cables for outdoors and extension cords.

Coaxial Cable Assemblies

Coaxial cables are important in transmitting signals at a great speed over long distances.

These cables are composed of a single conductor with a dielectric wrapped around it which is also covered by the outer metal shield.

We at Cloom design coaxial cables with special materials and processes to transmit signals faster.

However, regular coaxial cables also work well for everyday usage.

Automotive Wire Harnesses

All automobiles thrive on different cables allocated to perform designated functions.

At Cloom, we design high-quality automotive cable harnesses that are water and dust resistant and follow automobile ISO standards.

Furthermore, we also provide common wire assemblies that include SAE J-1128, TXL/GXL ratings, and overmold compounds.

Medical Device Cable Assemblies

Medical cable assemblies consist of special cables that transmit power, data, and high-quality videos.

Since these cables are used in a complex environment with sterilization and chemicals, they comply with ISO 13485 standards.

Cloom manufactures these special cables with high-end technology to withhold strong chemicals and autoclave sterilizations.

Cloom also provides in-house high-grade video connectors such as 11-pin/12-pin high-resolution video plugs.

Military Cables

Cloom manufactures the Mil-spec 38999 cables with corrosion-resistant conductor coatings and special wire jacket materials that you can easily assemble with connector systems.

However, these connectors require high-grade technical equipment such as insertion/extraction tooling, HIPOT test apparatus, torque wrenches, or crimpers to establish successful connections.

So, Cloom offers a wide range of ITAR-certified assembly options, tests, and assembly equipment to support your project and achieve your objectives.

Workers in the production room.

The Benefits of Cable Assemblies and Wire harness outsourcing

Here are a few benefits of outsourcing wire harness manufacturing.

- Expertise: An experienced wire harness manufacturer has made harnesses and assemblies for years, if not decades. The manufacturer has undoubtedly become an authority on wire harnesses thanks to their extensive experience in the field.

- Low Cost: Outsourcing lowers overhead and production costs in a low-cost country. Thus, your product will have lower prices, allowing you to attract more customers without compromising the quality.

- Efficient Production: When you outsource, you work with factories with the equipment and personnel to mass-produce wire harnesses. Here, the stocks never run out, and you can meet the need of your customers even when the prices are sky-high.

- Cheap Raw Material: As sourcing is now the headache of other companies you are doing the contract with, and they already have plenty of material, raw material cost substantially cuts down. Also, you can put this extra money into your running business for other tasks.

- Flexibility: Perhaps the greatest benefit is its flexibility to choose different manufacturers and deal with them for its needs. Also, if you need cabling with different specifications and designs.

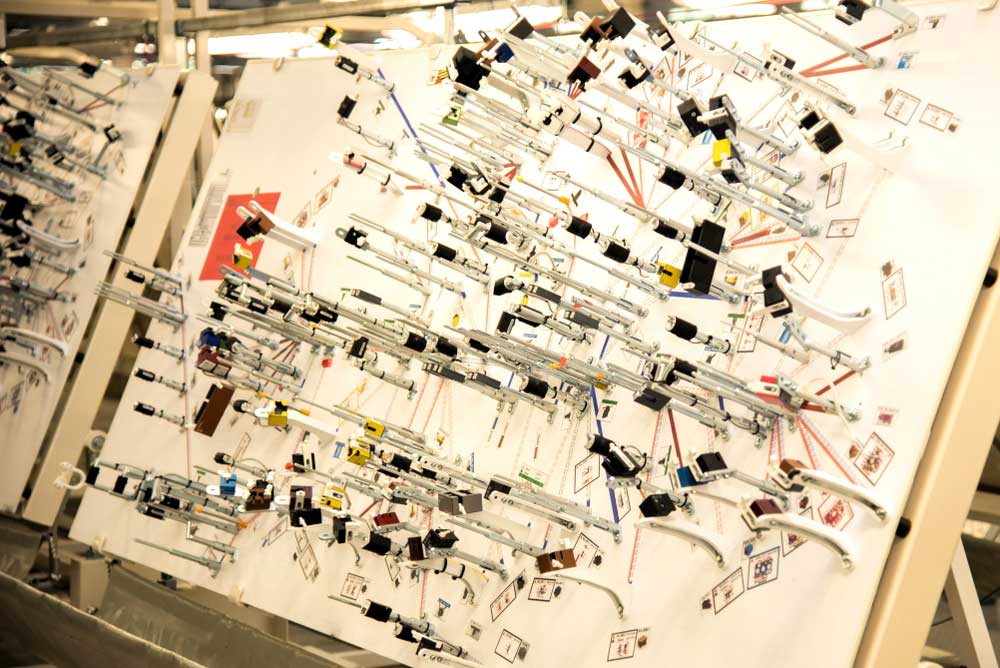

Testing the parts individually

What Your Cable Assemblies and Wire harness contract manufacturer (CM) Needs

A contract manufacturer can often make both cable and wire harnesses. They both have different building styles and require different things for manufacture.

For instance, a wire harness requires laying out on a panel with pegs, with different smaller strands in different dimensions.

Here, you must tell the CM what these dimensions are in 3D Models or documentation, whichever suits you best.

The accuracy of the built harness will depend upon how correct the details you gave them in the early stages are and how you communicated with them.

Furthermore, the greater the precision of requirements, the fewer issues will arise on the production side.

For your help, we have listed some basic things a contract manufacturer will need from you.

- List of wires and its specification (color, connector pinouts, nets…)

- Connector details with exact pin locations

- Material Bill with part specification

- Details of Assembly design with labeled locations, tolerance points, and other instructions

- Finished harness test cases

The Cable Assemblies and Wire Harness Manufacturing Process

The CM will follow these steps to manufacture cable assemblies per the requirements.

- Design Review: The CM will first check all the materials you provide and the design and discuss whether they are advantageous for the manufacturer. Also, they will go into the details of whether the material is available, its cost, etc., and look for replacements if some issue occurs.

- Material Prep: After the design review, the manufacturer will look for the supply and order the parts from the raw material source to start the process.

- Assembly Documentation: As the purchase of raw material is ongoing, the CM also develops assembly documentation featuring all the bases of the harness according to your input. So you can go through all the procedures and point out the problems before the start of the actual process.

- Harness Production: As they complete all the previous steps, it is time to start production. The assembly specialists will measure and cut the cable to length and then arrange it on the panel by the blueprints. Ultimately, they will tie the wire bundles, install the connectors, and fix labels over them.

- Quality Analysis: After assembling the wiring harness, they will test it to find any errors before the production process ends. If the appropriate system is there, we will verify the quality of the harness’s construction and labels and see how well it fits.

Production room wire harness manufacture

How to Qualify Cable Assembly and Wire Harness Manufacturer to Ensure a Successful Contract

To qualify a contract manufacturer for your production, look for the following aspects to ensure a successful contract.

Cable assemblies and wire harnesses: Equipment

A CM should have new cutting-edge technologies, which you don’t hold as a company.

The work will automatically boost speed if you manually manufacture the wires and hire a company with automated machinery.

Such a choice will be a wise decision.

Moreover, the more modern the machinery, the greater the quality of the produced material will be, which can also serve as a point of advertisement to attract customers.

Delivery Lead Times

At each order, you need to see how quickly you need your items delivered or how quickly your customers need you to deliver their products.

Moreover, your new producer must guarantee they can meet your production needs within a particular period if you want to continue working with them.

Here, you can consider a few strategies, such as

- Kan-Ban systems,

- Blanket orders,

- buffer numbers,

- and consignment inventory.

Many suppliers consider them for certain clients who require consistently fast delivery.

ISO 9001 Standards

ISO 9001 is a quality management system developed by the International Organization for Standardization to help businesses of all sizes implement a systematic approach to improving their operations via continuous improvement.

For instance, if you undergo a quarterly ISO audit of compliance, the auditor will analyze all the reported faults.

They will ask for evidence of your steps to prevent them from happening again.

Moreover, they will want to see your safety handbook and proof that you’ve made the workplace safer for everyone.

Also, they’ll want to know about any changes you’ve made to the rest of your operations to increase efficiency or better serve your customers.

Obtaining ISO 9001 certification is not the end goal; rather, it is a never-ending struggle to maintain approval as a quality business that shows quarterly improvement (on paper).

Conclusion

Assemblies and harnesses are important in almost all machinery.

You can hire a contract manufacturer and quickly outsource your work for better-quality products.

Cloom has made its name as a leading contract manufacturer for outsourcing harness making.

We hold experts in designing and manufacturing custom wire/cable harnesses.

Hence, you can take our services in almost anything crucial. To get the work done, contact us now.