Wiring a vehicle generally involves two kinds of wiring, chassis wiring harness, and power transmission wiring.

Although both wire types are essential, they categorically serve different functions.

If you’re unaware of what they do, you could end up causing severe damage to your car.

Power Transmission Wiring Understanding

This wiring carries electrical signals from the engine to whichever components.

Typically, it consists of aluminum and copper with insulation to protect against elements like voltage spikes and short circuits.

Further, the wiring often bundles together in the loom, allowing for easy routing via the engine bay.

The power transmission wiring harness distribution is as follows:

- High voltage power cable – connected from the junction box specifically for high voltage to the power battery.

- Motor control cable – connects the motor control to the high voltage junction box.

- The fast charging cable is connected from the high-voltage junction box to the port that allows fast charging.

- The slow charging cable connects the car charger to the slow charging port.

- Wiring harness for the high-voltage accessory supply– connect from the wiring harness between the AC, PTC, vehicle charger, and DCDC to the high-voltage junction box.

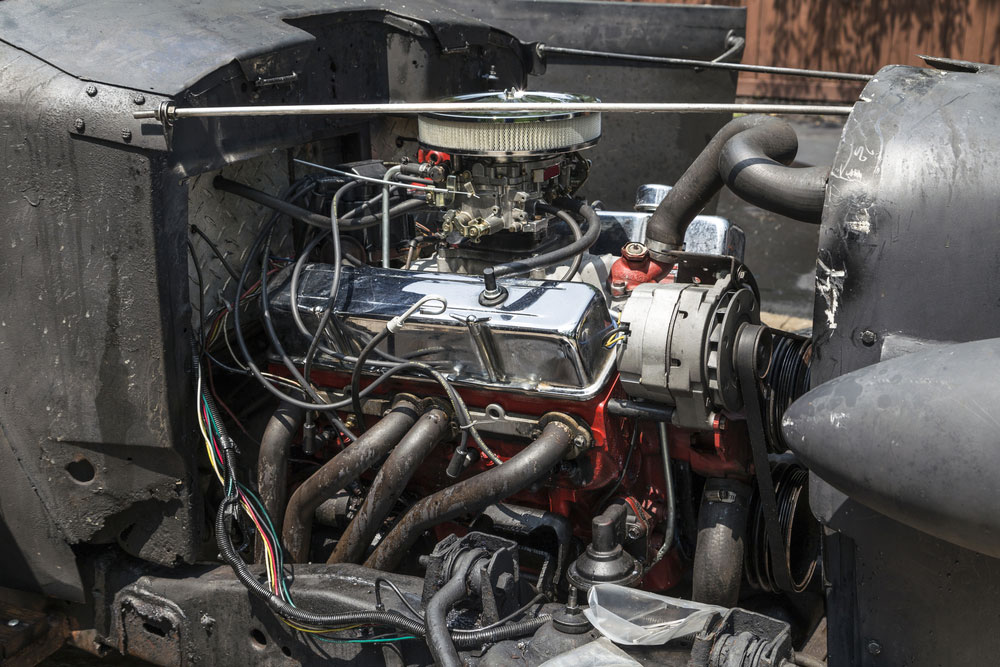

Power transmission wiring on the engine

Chassis Wiring Understanding

Aside from the primary ignition, starting, and charging circuits, a vehicle has several other wires responsible for powering components such as radio, heating features, electrical motors, magnet functioning locks, lights, and sensors.

One may open and close such circuits using switches or relays.

Chassis wiring carries electrical signals from components mounted on a car’s chassis, like the headlights and turns signals, to the primary fuse box.

That said, chassis wiring harnessing setups typically include the following groups:

The front wiring harness comprises air conditioning, instrumentation, battery wiring harness, and front light assembly.

The roof wiring harness comprises a roof light, door, and audio speaker.

The rear wiring harness comprises the tail light assembly, license plate light, and luggage compartment.

This wiring uses aluminum or copper but is not insulated in the same manner as power transmission wiring.

You route it via the holes in the car’s body, making it more susceptible to damage from water and other elements.

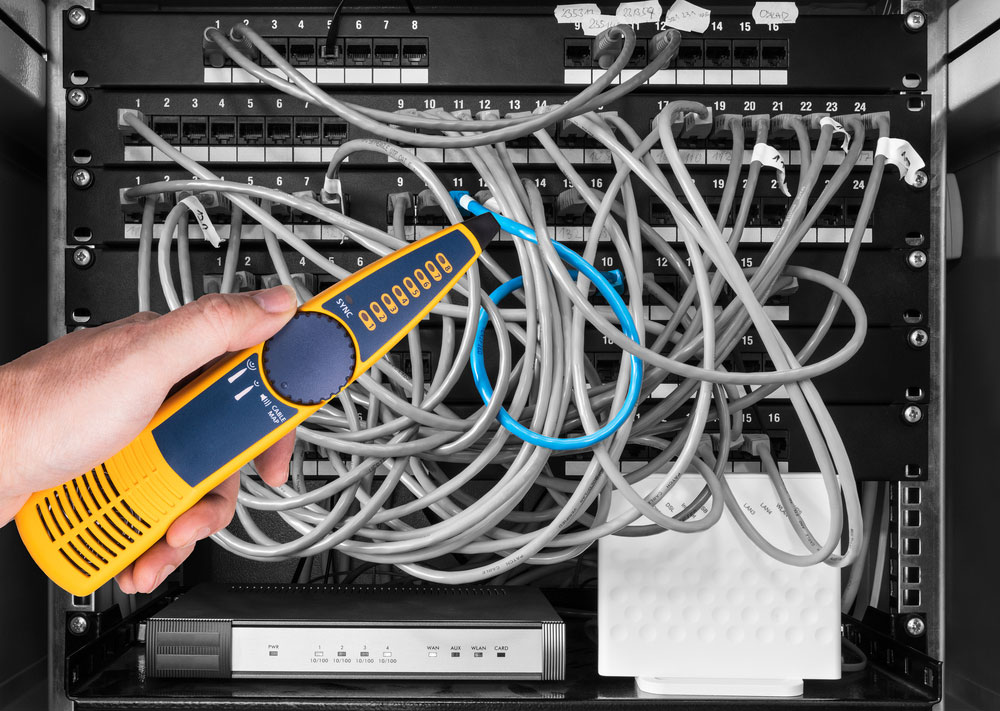

Chassis wiring.

Chassis Wiring vs. Power Transmission Wiring Harness: Difference

Now you understand the chassis and power transmission wiring harness, but how do they differ?

Power Transmission Wiring Needs Thicker Gauge Wires

A vehicle’s chassis wiring comprises separately routed wires, whereas a power transmission has wires tied together in a bundle.

The reason is that the wires for the power transmission have to handle higher levels of current than their chassis counterparts.

The power transmission wiring should be able to hold out against voltage performances of, for example, 600/900 VAC or 1000/1500 VDC.

And regarding the performance of the high-voltage elements, the wire should handle a current reaching 250A to 400A.

Therefore, they must be of a thicker gauge to prevent short circuits.

Power Transmission Wiring Offers Shielding

For domestic OEMs, we recommend using shielded cables for high voltage because these cables lower the effect of electromagnetic interference (EMI) and radio frequency interference (RFI) on the car system.

Power Transmission Wiring Has Some Overheating Problems

This wiring harness typically comprises several conductor wires comprising aluminum and copper in bundles.

Also, they’re insulated with a dielectric material to prevent the conductor wires from touching, which would cause a short circuit.

But the problem with such wiring is the low air conduction, which can lead to overheating and, as a result, issues such as electrical power loss and voltage drop.

Power Transmission Wiring Follows more strict design requirements

Besides powering lamps, the engine, and other devices, power transmission wiring can also connect the battery to the alternator and starter.

The wire is typically a stranded copper conductor with PVC insulation or other appropriate dielectrics.

For example, it should have varying temperature resistance of 125℃, 150℃, and 200℃ and a low temperature conventional of -40℃ with a broader wire wall of 0.6 to 1.1mm.

Power transmission Wiring needs more protection measures

Chassis wiring often implements elements like circuit breakers, fuses, and grounding as a protective measure for an appliance and its user.

In the case of power transmission wiring, it implements elements like lightning protection, insulators, and grounding protection measures.

| Differences | Chassis/Low Voltage Wiring | Power Transmission/High Voltage Wiring |

| Gauge | It’s smaller | It’s larger |

| Voltage and current levels | Voltage is lower, but the current is high | Voltage is higher, but the current is low |

| Distance | Suited for shorter distances | Suited for longer distances |

| Purpose | Built to power and control vehicle components | Built to transmit electrical power from one place to another |

| Applications | Automobiles, aircraft, boat | Power plants, electrical grids, transmission lines |

| Protection measures | Requires the use of fuses, circuit breakers, and grounding | Requires using insulators, lightning protectors, and grounding |

| Examples | Engine, headlights, dashboard | Insulators, lightning protection, grounding |

Thick gauge wire

Common Problems with Chassis Wiring and Power Transmission Wiring

The following are some of the aspects that will most likely lead to trouble within specific components of your vehicle:

Loose Connections:

This particular issue tends to occur when you fail to fasten the electrical components of both wirings, leading to an electrical current flowing via the wrong path.

This type of issue can lead to a system failure or malfunction and, in some cases, a fire or other hazards.

Open Circuit

The term refers to a break in the electrical line, usually due to physical separation in the wiring.

To diagnose the issue, you should examine the harness for signs of a severed connection.

Also, other obvious damages like fraying or burns will quickly lead you to the area where there’s a broken connection.

Stretched Wiring

This is another common issue in the transmission wiring harness.

It happens because of extreme tension on the harness or incorrect installation during the car’s assembly in the factory or after servicing.

Such a problem can lead to misfires and shifting issues.

You can diagnose the issue by reviewing the wiring harness and looking for any obvious signs of additional tension in the lines. If you see something, you should have a professional adjust the lines.

Corroded Wires

This is a fairly common problem that happens with transmission wiring harnesses as they get older or if you expose a vehicle to moisture due to leaks in the system or from the environment.

Corrosion can result in many problems like shorting, damage to the car’s electrical system, loss of power, or even fire.

Diagnosing the problem involves inspecting the harness for any signs of damage like a greenish build-up or white residue in the wires.

And you can fix the problem by cleaning the areas of contamination using a wire brush together with a solution consisting of water and baking soda.

Faulty Connectors

This happens when a connector undergoes damage, becomes loose, and experiences corrosion.

Diagnosing the issue involves checking for loose connectors.

If you find any, gently wiggle them and see if they connect. In case they don’t, then you can try resetting them.

Damaged Insulation

Insulation that has suffered some damage can lead to strange noises in the electrical system, intermittent power issues, and dimming or flickering lights.

To diagnose the issue, you should have your technician check the area under threat in your wiring harness for any signs of damage.

And in case there are any, you can replace or repair them.

Wire Touching the Ground

This type of issue can result in electrical problems like starting issues, engine stalling, dimming or flickering lights, and static radio.

In most cases, you can resolve the problem by adjusting or fixing the wire, the ground, or both.

In situations where the parts have undergone severe damage, there’s no other solution but to replace the faulty wires.

Conclusion

The chassis wiring, typically made of copper or aluminum, carries low-voltage signals, and manufacturers employ it in accessories like horns and lights.

On the other hand, power transmission wiring has high-voltage signals; you can use it when charging the battery and starting the engine.

It also tends to be longer and has a higher resistance level than its counterpart.

At Cloom, we deal with all kinds of wiring harnesses, so if you need help with your wiring, feel free to contact us.